license tests by hardness|different types of hardness tests : exporters Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. Significance and Use. 4.1 Vickers and Knoop hardness tests have been found to . Anti-Convulsivantes - PedAjuda - Condutas e Prescrições Pe.

{plog:ftitle_list}

Assetto Mods admin 2022-07-23T15:47:37+10:00 Categories: Car Mods, Mitsubishi | Tags: Street Cars, Touge | Mitsubishi Lancer EVO X FQ-400 Car Mods , Mitsubishi

standards for hardness testing

mcmurray test and apley compression test

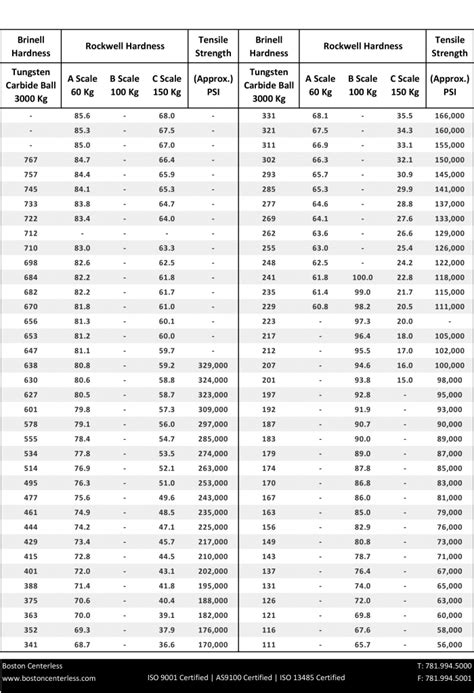

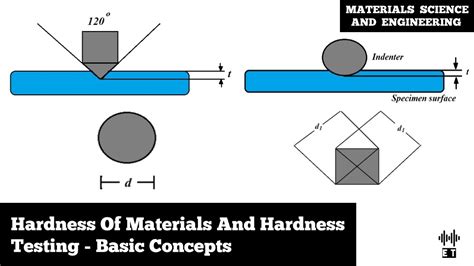

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.The principle of electronically controlled and permanently monitored load application . Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality . Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. Significance and Use. 4.1 Vickers and Knoop hardness tests have been found to .

This article provides an overview of common hardness testing methods for metals, comparing their applications, benefits, and drawbacks, and includes a comprehensive .

A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by .1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth . The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness testing is used for two general .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

1. Rockwell Hardness Testers. Rockwell hardness testers are the most commonly used of all the types of hardness testers. The Rockwell method offers a quick and accurate measure of hardness on almost all metals and . The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings. Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for .

standard hardness testing methods

Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of .Mohs Hardness Test: This qualitative test ranks minerals based on their scratch resistance against standard materials with known hardness values. It’s commonly used in geology and mineralogy for mineral identification. These hardness testing methods serve various purposes, from quality control in manufacturing processes to material selection . Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N).

Buy a test kit for carbonate hardness and general hardness. Unlike regular tap water where you only check the general hardness (GH), you need to test aquariums for their carbonate hardness (KH) as well. Look at pet stores or online for a test kit that contains solutions for both KH and GH so you can get a complete understanding of your aquarium .

Quiz yourself with questions and answers for Class C Water Operator License Exam, so you can be ready for test day. Explore quizzes and practice tests created by teachers and students or create one from your course material. . Water hardness is caused by. Name one advantage to using centrifugal pumps. When turning a centrifugal pump off .Brinell Hardness Test: This test involves pressing a large ball into the material's surface to measure hardness. Rockwell Hardness Test: The Rockwell test utilizes a cone-shaped diamond or steel indenter to assess hardness. Mohs Scale Advantages and Disadvantages. While the Mohs Scale is relatively simple and accessible, it lacks precise .

(4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity must be met to obtain the same HB value, that is, the opening angleφ of the indentation is equal.. Method: The same HB shall be measured for samples with . Buehler is a recognized leader in materials preparation, testing, and analysis, ensuring highly credible and practical insights. This source is valuable for readers seeking a thorough understanding of hardness testing techniques and their applications. 2. Academic Journal: “Advancements in Hardness Testing Techniques: A Review . Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific varieties of a hardness test determined by factors such as the type of indenter, applied force, and procedure of force application.

About Hardness Tests. The hardness test developed by Friedrich Mohs was the first known test to assess resistance of a material to scratching. It is a very simple but inexact comparative test. Perhaps its simplicity has enabled it to become the most widely used hardness test. Since the Mohs Scale was developed in 1812, many different hardness .Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy.The large size of indentation and possible damage to test-piece limits its .

You can’t use the Rockwell method for testing the hardness of .020″ shim stock if it’s supposed to be 60 HRC. Just be aware that there are minimum thicknesses in the 0.040″ and under range so you can look up the reference if you should . One key to identifying mineral species is to test its hardness. Mineral hardness tests can be performed at home or on a rockhounding field trip. There are necessary tools for express hardness testing: A fingernail, a . 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information . The units of measurement of tablet hardness are Kilogram (kg), Newton (N), Kilopond (kp), Pound (lb), and Strong-Cobb (SC). Pharmacopoeial or Official Tests for the Evaluation of tablets. These tests are specified either in individual product monographs or general monographs. Identification Tests of Tablets

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation. 1.3 The portable hardness testers covered by this test method are verified only by the indirect verification method. Although the portable hardness testers are designed to employ the same test conditions as those defined in the standard test methods, the forces applied by the portable Rockwell and Brinell testers and the depth measuring systems of the portable .The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was chosen to . If you want to identify a mineral, a hardness test can give you valuable information. You'll probably need to do a scratch test to in order to find what minerals are harder than your sample. Then, you can refer to the Mohs hardness scale, which ranks common minerals by hardness. This scale was developed over 200 years ago and it's still the .

High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the Steps for Performing the Mohs Hardness Test . Find a clean surface on the specimen to be tested. Try to scratch this surface with the point of an object of known hardness, by pressing it firmly into and across your test specimen.For example, you could try to scratch the surface with the point on a crystal of quartz (hardness of 9), the tip of a steel file (hardness .

Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter. A part’s testing surface and seating surface must be properly prepared prior to testing. Measuring the hardness of materials is a fundamental aspect of material science and engineering, involving various test methods each suited to specific types of materials and applications. These methods not only help in determining the hardness but also provide insights into other material properties like strength, wear resistance, and ductility.

A casa-grande é composta de 12 ambientes. Há 14 janelas, com destaque para a do centro na fachada sul. Essa janela tem um . Ver mais

license tests by hardness|different types of hardness tests